| Type | (Cust.) Art. no. | d | d2 | bar | i | z | e | CAD | Legend | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | SO 41821-8-10 | Art. no. | 018.1820.083 | d | 10.0 mm | d2 | 8.0 mm | bar | 125.0 bar | i | 7.0 mm | z | 14.0 mm | e | 6.5 mm | CAD | Download | |

| Type | SO 41821-10-4 | Art. no. | 018.1800.167 | d | 4.0 mm | d2 | 10.0 mm | bar | 125.0 bar | i | 7.0 mm | z | 13.0 mm | e | 3.4 mm | CAD | Download | |

| Type | SO 41821-10-5 | Art. no. | 018.1800.170 | d | 5.0 mm | d2 | 10.0 mm | bar | 125.0 bar | i | 7.0 mm | z | 13.0 mm | e | 4.0 mm | CAD | Download | |

| Type | SO 41821-10-6 | Art. no. | 018.1800.175 | d | 6.0 mm | d2 | 10.0 mm | bar | 125.0 bar | i | 7.0 mm | z | 13.0 mm | e | 4.5 mm | CAD | Download | |

| Type | SO 41821-12-6 | Art. no. | 018.1800.215 | d | 6.0 mm | d2 | 12.0 mm | bar | 100.0 bar | i | 7.0 mm | z | 14.5 mm | e | 4.5 mm | CAD | Download | |

| Type | SO 41821-12-8 | Art. no. | 018.1800.225 | d | 8.0 mm | d2 | 12.0 mm | bar | 100.0 bar | i | 7.0 mm | z | 14.5 mm | e | 6.0 mm | CAD | Download | |

| Type | SO 41821-15-8 | Art. no. | 018.1800.400 | d | 8.0 mm | d2 | 15.0 mm | bar | 40.0 bar | i | 8.0 mm | z | 15.5 mm | e | 6.5 mm | CAD | Download | |

| Type | SO 41821-15-10 | Art. no. | 018.1800.410 | d | 10.0 mm | d2 | 15.0 mm | bar | 40.0 bar | i | 8.0 mm | z | 15.5 mm | e | 8.0 mm | CAD | Download | |

| Type | SO 41821-18-10 | Art. no. | 018.1800.575 | d | 10.0 mm | d2 | 18.0 mm | bar | 40.0 bar | i | 8.0 mm | z | 16.5 mm | e | 8.5 mm | CAD | Download | |

| Type | SO 41821-18-12 | Art. no. | 018.1800.580 | d | 12.0 mm | d2 | 18.0 mm | bar | 40.0 bar | i | 8.0 mm | z | 16.5 mm | e | 10.0 mm | CAD | Download | |

| Type | SO 41821-22-12 | Art. no. | 018.1800.730 | d | 12.0 mm | d2 | 22.0 mm | bar | 25.0 bar | i | 8.0 mm | z | 18.5 mm | e | 10.0 mm | CAD | Download | |

| Type | SO 41821-22-13 | Art. no. | 018.1800.735 | d | 13.0 mm | d2 | 22.0 mm | bar | 25.0 bar | i | 8.0 mm | z | 18.5 mm | e | 11.0 mm | CAD | Download | |

| Type | SO 41821-22-14 | Art. no. | 018.1800.740 | d | 14.0 mm | d2 | 22.0 mm | bar | 25.0 bar | i | 8.0 mm | z | 18.5 mm | e | 12.0 mm | CAD | Download | |

| Type | SO 41821-22-15 | Art. no. | 018.1800.745 | d | 15.0 mm | d2 | 22.0 mm | bar | 25.0 bar | i | 8.0 mm | z | 18.5 mm | e | 12.0 mm | CAD | Download | |

| Type | SO 41821-28-17 | Art. no. | 018.1800.868 | d | 17.0 mm | d2 | 28.0 mm | bar | 16.0 bar | i | 10.0 mm | z | 22.5 mm | e | 15.0 mm | CAD | Download | |

| Type | SO 41821-28-18 | Art. no. | 018.1800.870 | d | 18.0 mm | d2 | 28.0 mm | bar | 16.0 bar | i | 10.0 mm | z | 22.5 mm | e | 16.0 mm | CAD | Download | |

| Type | SO 41821-28-19 | Art. no. | 018.1800.875 | d | 19.0 mm | d2 | 28.0 mm | bar | 16.0 bar | i | 10.0 mm | z | 22.5 mm | e | 16.0 mm | CAD | Download | |

| Type | SO 41821-28-22 | Art. no. | 018.1800.900 | d | 22.0 mm | d2 | 28.0 mm | bar | 16.0 bar | i | 10.0 mm | z | 22.5 mm | e | 19.0 mm | CAD | Download | |

| Type | SO 41821-10-6,35 | Art. no. | 018.1800.177 | d | 6.35 mm | d2 | 10.0 mm | bar | 125.0 bar | i | 7.0 mm | z | 13.0 mm | e | 4.5 mm | CAD | Download | |

| Type | SO 41821-15-9,52 | Art. no. | 018.1800.408 | d | 9.52 mm | d2 | 15.0 mm | bar | 40.0 bar | i | 8.0 mm | z | 15.5 mm | e | 8.0 mm | CAD | Download | |

| Type | SO 41821-22-12,7 | Art. no. | 018.1800.732 | d | 12.7 mm | d2 | 22.0 mm | bar | 25.0 bar | i | 8.0 mm | z | 18.5 mm | e | 11.0 mm | CAD | Download |

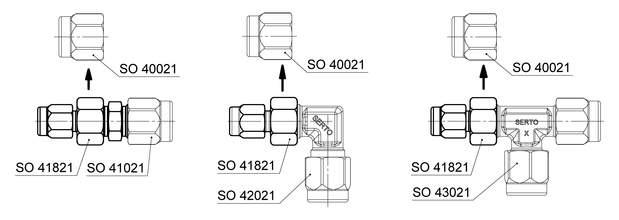

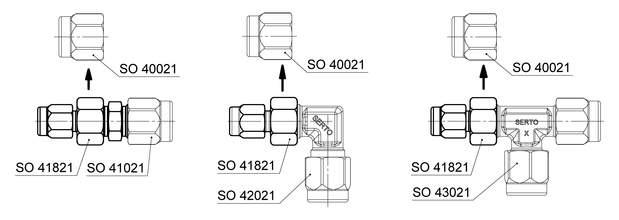

Reduction union

for union body

SO Code:

-

Art. no.: -

Technical details

Additional information

The SO 41821 reduction can be screwed onto all SERTO moulded parts with a matching thread and must be tightened with 1/4 turn. This combination enables further tube reductions.

Sealing principle: On assembly, the sealing edge of the transition piece presses into the SERTO moulded part. This produces a perfect metallic seal. We recommend that the thread is secured against accidental unscrewing by means of a suitable liquid adhesive.

Sealing principle: On assembly, the sealing edge of the transition piece presses into the SERTO moulded part. This produces a perfect metallic seal. We recommend that the thread is secured against accidental unscrewing by means of a suitable liquid adhesive.

Conversion for "d" for inch tubes:

6,35 = 1/4

9,52 = 3/8

12,7 = 1/2

6,35 = 1/4

9,52 = 3/8

12,7 = 1/2

The SO 41821 reduction can be screwed onto all SERTO moulded parts with a matching thread and must be tightened with 1/4 turn. This combination enables further tube reductions.

Sealing principle: On assembly, the sealing edge of the transition piece presses into the SERTO moulded part. This produces a perfect metallic seal. We recommend that the thread is secured against accidental unscrewing by means of a suitable liquid adhesive.

Sealing principle: On assembly, the sealing edge of the transition piece presses into the SERTO moulded part. This produces a perfect metallic seal. We recommend that the thread is secured against accidental unscrewing by means of a suitable liquid adhesive.

Conversion for "d" for inch tubes:

6,35 = 1/4

9,52 = 3/8

12,7 = 1/2

6,35 = 1/4

9,52 = 3/8

12,7 = 1/2