Why SERTO?

The advantages of the SERTO principle

SERTO unions impress with their unique radial system. The diverse basic elements in the standard range can be combined with connecting parts from SERTO. The modular system make countless, individual solutions possible that are metallically tight, very compact and available for immediate delivery.

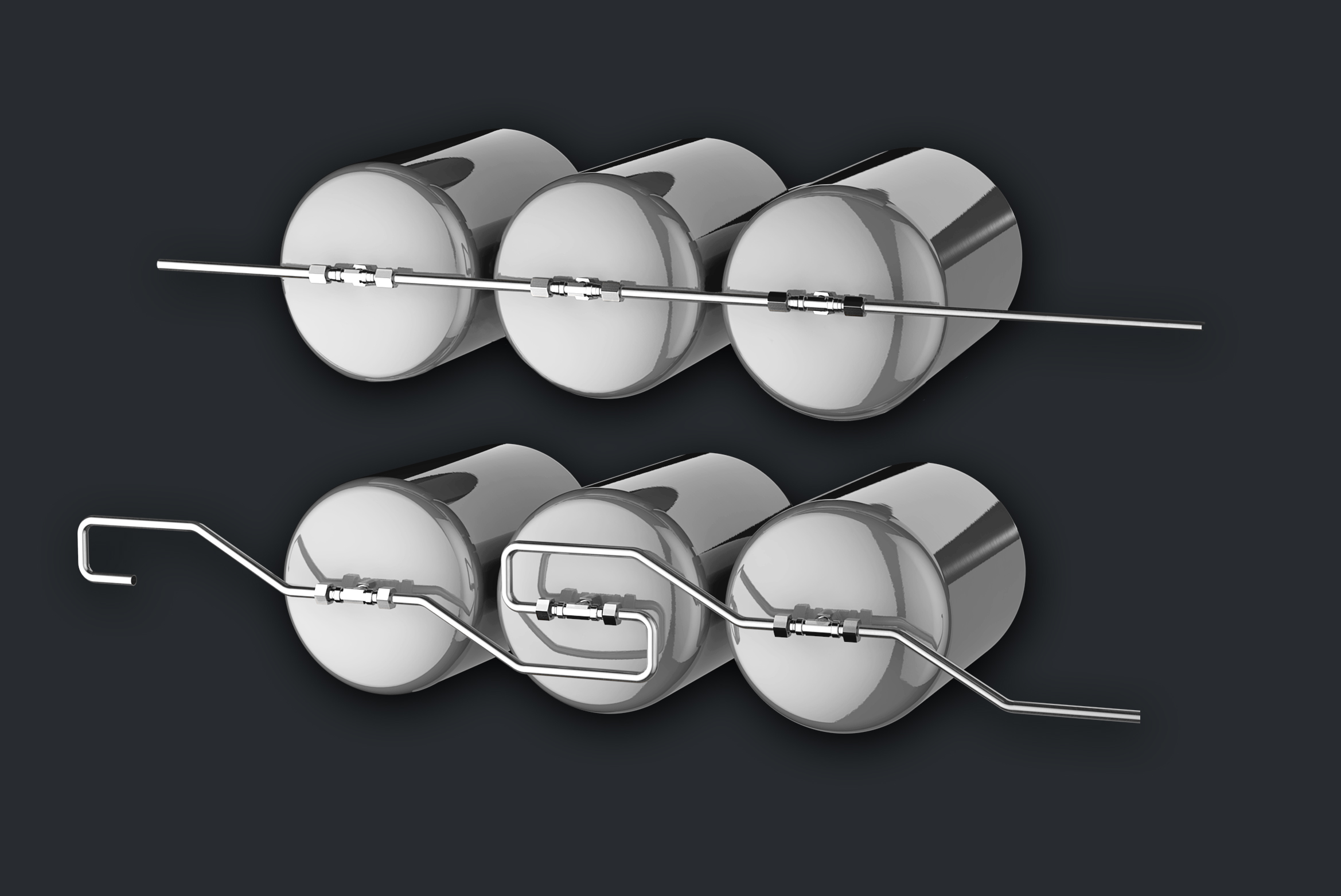

The radial principle

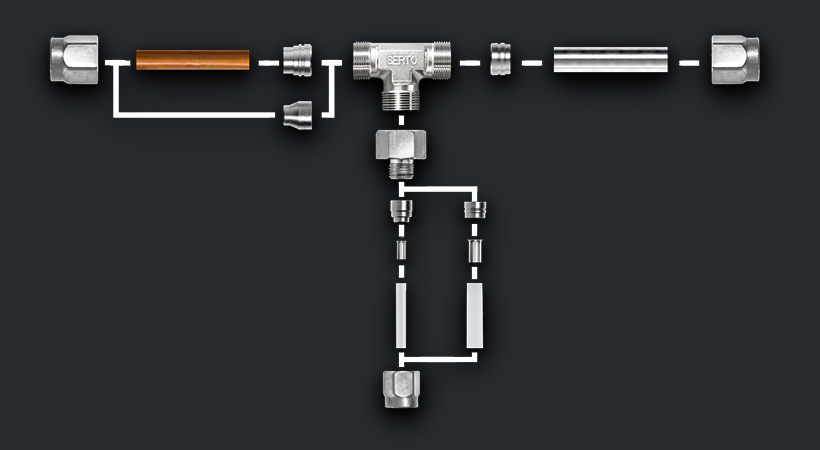

The modular kit system

SERTO components can be combined with each other like in a modular system kit. Important basic elements in the standard range include

- Straight fittings

- Male connectors with various threads

- Elbow fittings

- Bulkhead fittings

- Single banjos

- L, T and cross unions

Combined with SERTO connection parts, countless individual solutions are created that are metallically tight, very compact and available for immediate delivery.

Find out about products and services

Reduce costs

Save on design costs

Save on system costs

Save on procurement costs

In the example shown, with SERTO unions you benefit from 70% shorter pipelines without bending effort.

With a 22 tube, this corresponds to a saving of about 75%.

Safety in use

The metric fine thread of the SERTO union nuts proves to be self-locking and extremely vibration-resistant. The nuts do not loosen when exposed to shocks or vibrations.

As a true compression ferrule union, the SERTO fitting does not damage the tube or hose during assembly.

The full wall thickness is retained

Save space

The shortest of all connections is straight. Due to connection via flat surfaces, all components that are connected with SERTO unions can be removed radially from the pipeline system. No compensating bends are necessary and pipeline routing can be carried out with the smallest possible space requirement.

With SERTO unions, the base bodies and the corresponding nuts are smaller. These few saved millimetres can make a decisive difference in cramped installation conditions, where more pipelines can be routed next to each other in the same installation space.

The standard compression ferrule in the nut can be exchanged for a reduction compression ferrule so that you can connect tubes with a smaller diameter using the existing union. The installation dimensions remain identical.

Safe assembly

All SERTO unions have an internal tightening limit that shows the fitter that they have finished assembly. In the stainless steel SOL series, the limit is designed as a stop. Over-assembly is impossible, no matter what type of pipe or hose you connect. The safety of the connections is increased enormously and the risk of leaks is eliminated.

Due to its design, the SERTO compression ferrule has a slight resetting property. After dismantling the union, the compression ferrule relaxes and is free to rotate on the tube. During repeat assembly, the compression ferrule is pressed firmly onto the tube again and seals reliably.

High flexibility

The SERTO modular system provides a flexible range of solutions only requiring a small number of parts. A few additional parts allow you countless new connection options.

Especially for plant manufacturers who produce customised products, there are thousands of combinations. They are flexible in connection size and connection thread. This saves space not only in your application, but also in your warehouse.

Adjustable unions in all materials allow you to discharge rigid pipelines at different, individually adjustable angles. Plugs securely close lines that are no longer needed.

For the most part, we only assemble the unions once you place your order. This makes it possible for us to respond to your wishes and adapt the sealing material.

Save time

Installing pre-assembled lines in a system reduces production times. Having to loosen fewer nuts during servicing reduces downtime.

Thanks to their flat surface, SERTO unions can be installed directly radially in a pipeline system without having to move, bend or dismantle pipes.

Save weight

SERTO carries screw joint assortments in six materials. In weight-critical applications such as in railway engineering or aeronautics with normal pressure requirements, it is worth taking a look at our plastic or aluminium products.

Thinner-walled tubes, for which we recommend the use of support sleeves, may also be suitable. We will be happy to advise you on which products and combinations could be an alternative for you.